What would you like to see on

this site?

let us know let us know |

|

Cherwell

Junction

- 00 Gauge layout |

| |

|

|

|

|

|

David t’s Hook Norton brewery, one of the main features

on ‘Cherwell’. |

|

Cherwell, is a scenic OO gauge, 26 feet 6inches

by 10 feet 6 inches, four track mainline with an integral branch

line. It features working automatic signals and has largely

scratch built buildings.

The 12 months before being invited to the prestigious Warley Model Railway

Club's National Railway Exhibition at the NEC in 2006, additional momentum was gained on buildings lighting and other general scenery work.

The layout was built mainly to display scale length mainline

trains, those being run reflecting the varying interests of

the membership. Trains run are usually British outline, but

can come from any part of the UK mainland and from any date

between about 1900 and the present day. On club nights the layout

is usually run on the first Thursday of every month. |

| |

|

|

| |

|

Control |

One half of the main control panel on ‘Cherwell’ |

|

There are four control panels - the main one at the front

for the main lines, loops, rear 'fiddle' yard and some of

the branch line; the branch line; the engine shed and a small

one for the triangle on the tramway. Point motors are activated

by the 'electric pencil' method from the control panels. All

track is split into sections and 'Cab' control is used.

There are four controllers for the mainline - up and down

main and up and down relief into the fiddle yards, two controllers

for the branch (upper and lower) and one controller each for

the engine shed and tramway. Rotary and toggle switches allow

each section to be switched off or set to different controllers,

allowing trains to change tracks easily. Trains can be changed

from the outside track to the inside and vice-versa if required.

There are sections approximately every foot in the engine

shed area to allow each locomotive to be moved separately

and the turntable is powered from the engine shed controller

when a switch is thrown. All the mainline platforms and the

fiddle yard are split into two sections so that two trains

can be present at a time, space permitting. Feedback controllers

running off a 20 Volts AC feed are used. |

| |

|

|

| |

|

Stock |

Great Western steam locos on shed – ‘Cherwell’. |

|

As many members have preferred eras, we prefer to display a

quality and interest of stock rather than trying to set a particular

time period. Much of our members stock is super-detailed ready-to-run,

kits or scratch built.

|

| |

|

Landscape |

The south oxfordshire seaside scene at ‘Cherwell’ beach. |

|

Mainly interior filler sculpted over an expanded polystyrene

former in a plywood frame, painted and covered with coloured

scatter material. Extensive use is made of proprietary textured

plastic (polystyrene) sheet for roadways and walls. |

| |

|

Buildings |

David t’s Scratch built building of ‘Tyseley’ station model. |

|

Permanent buildings are made entirely from polystyrene (plasticard).

Some are made from scratch using textured polystyrene (plasticard)

sheets and some are modified kits. The buildings chosen are

mainly from the Edwardian period or earlier in order not to

clash with varied stock that is run.

|

| |

|

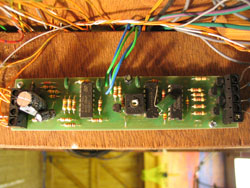

Wiring |

‘Spaghetti Junction’ the wiring required to

run ‘Cherwell’!

|

|

The 16 boards are connected together with mainly 20-way connectors

from RS. These connect the track sections, signals, lighting,

point motors and switches for control panel indicators to the

control panel. There is a common return. Controllers –

‘Cab’ control is used. |

| |

|

Track |

The micro-switches attached to the H & M point motors used

to change points on ‘Cherwell’. |

|

Track is all standard PECO Streamline Code 100. Points are all

live frog (‘Electrofrog’), with each part switched

by micro-switches attached to the H & M point motors under

the baseboards. The point motors turn a vertical brass tube

with a horizontal steel wire switching the points directly,

above the boards. Up to 2 or 3 points are sometimes switched

at once when a route is set, e.g. for a crossover between 2

tracks. Point motors are activated by the 'electric pencil'

method from the control panels. |

| |

|

Signalling |

The electronics for the signal including

infra red sensor and

timer. |

|

The layout features automatic colour light signals, operated

by rolling stock passing over a light sensor in the track which

sets the signal to red.

The signal returns to yellow and green using a timer once the

train has passed. Many signals are interlocked into the track

layout, so will show 'red' if the points are set against them.

The signal posts are made from brass tube and the heads are

proprietary. Starter and shunting signals on the main station

can be set manually. |

|

|

|

| Back to Top |

|

|

| |

|

|

Cherwell Journey |

| |

This is a description of a trip around our large 'OO' layout 'Cherwell Junction', written from the perspective of a train passenger.

Starting from the bridge over the railway which carries both Cherwell Junction and Cherwell Lower station buildings, we first examine the structures. Cherwell Junction station building was built by the Great Western Railway in red brick with a slate roof in the Edwardian era. It has two large passenger entrances and three footbridges leading down to the six platform faces. One platform is sheltered under the bridge carrying Cherwell High Street and a tramway. Various Edwardian and older buildings line the High Street, mainly shops, but also including the Mason's Arms pub and a late fifteenth century half-timbered house. The remaining two platforms each have two waiting rooms and a canopy over much of their length.

Cherwell Lower station building is Victorian and was built by the Midland Railway. It is roughly square in plan and is again built from red brick with a slate roof, but is smaller than the Cherwell Junction building, although the stonework is more ornate. We descend the footbridge to the single platform. There is a run-round loop and a few goods sidings. A brick-built bridge brings the road down from the town to the goods yard. There is a small, standard Midland Railway brick and wood signalbox with a slate roof, a loading dock, coal staithes and a grounded railway van body in use as a hut. Cherwell Junction North signalbox is visible across the Cherwell Junction tracks, clinging to the wall above the railway. It is a standard GWR Victorian timber design, held on four heavy beams and has a gable-ended roof with tall finials each end and pierced ridge tiles.

On leaving Cherwell Lower we pass under the road bridge and alongside the platforms of Cherwell Junction. As we start to head towards a tunnel with two double portals for the Cherwell Junction lines and a single portal for the Cherwell Lower line, we pass Cherwell Junction South signalbox in the middle of the mainline tracks. This built to a GWR standard design in brick and timber with a hipped slate roof. On the other side of the tracks there is a timber yard with stacks of timber and crates awaiting collection or delivery. On the left of our track is Cherwell Junction Engine Shed, which manages to cram a standard GWR two-road engine shed, a standard coaling stage and a large turntable into a very tight site. There are a few sidings, a grounded coach body and a sand drying shed. The engine shed is in a deep cutting with a very tall stone retaining wall. Past the engine shed the single line curves to the right and starts to climb and we enter a short tunnel.

On leaving the tunnel we pass a red sandstone cove, alive with seabirds and bathers. The railway runs along a stone wall past the choppy sea and into a second short tunnel. The tracks then climb for some distance, passing a fan of sidings on the mainline with some men working below. Just before the line curves to the right again, we pass the run-round loop and sidings of a tramway depot on the right. On the left, at a lower level, is an ornate brewery building.

There are rows of terraced houses with small back yards to the right of the railway as we pass through a lattice girder bridge over the mainline, where the line levels and soon enter another tunnel as the train slows for the first station.

On leaving the tunnel we arrive at the halt. This is a simple passing-loop station with one wooden platform supported on stilts from the road below. There is a small Midland Railway red brick-walled and slate-roofed cruciform waiting shelter on a brick plinth, a wooden ground frame building and a wooden platelayers' hut. We soon depart and cross a small steel bridge over a tramway and go into a cutting as the line again curves to the right and enters another short tunnel.

As it emerges from the tunnel, the line passes above some sidings on a very high retaining wall with occupied arches underneath and crosses another steel lattice bridge into journey's end at Cherwell Town station. First we pass the goods yard on the left with huts, a loading dock, a cattle dock and a weighbridge with hut. Next, the small standard MR slate-roofed brick and timber signalbox is passed on the left and the train arrives at the main platform. There is also a short bay platform for push-pull passenger services. The MR platform building is wooden with a flat roof and there is a water tower and separate coaling stage. The main entrance building is the same design as Cherwell Lower station building.

JT. |

| |

|

Schedule for Branch Line Operations during shows

MAIN OBJECTIVE - is to provide a varied operation of a typical branch-line in pre-Beeching days.

Acceptable steam outline engines - only use tank engines, ideally 0-6-0, or 0-6-2 and 2-6-2 that have proved to run consistently both up and down the branch with no derailments. Tender locos, especially those with leading pony trucks, have on several occasions proved problematic with derailments (often in hard to reach places!) so should not be run.

Passenger stock - Only 2 (TWO) passenger sets of no more than 3 carriages (4 if 4 wheeled coaches) should be in operation at any time. These operate by passing at the “passing loop” station.

Goods stock - There should be NO MORE THAN 8 or 9 goods wagons at EACH branch terminus station, from which a goods consist is created of no more than 5 wagons plus the addition of a brake van to travel from one station to the other. Goods wagons would typically be 4 wheeled stock such as vans, open wagons for coal and other loads and perhaps a flat wagon plus load or two. It would be unlikely there would be more than a couple of bogie wagons on the branch line.

Goods trains should be shunted as soon as possible on arrival and wagons should be shunted to their appropriate unloading/loading bay. It would be unlikely there would be more than 2 coal wagons at each station, due to the size of the loading areas. Whole rakes of a single wagon type seems unlikely!

Diesel traction - DMU single, double or triple passenger consist are acceptable as an alternative to steam hauled trains.

During a show a sequence of trains should be run over the branch line that follows one of the following guides:

2 x passenger services, crossing at the passing loop station.

1 x passenger and 1 x goods train, passing at the passing loop station

2 x goods train, passing at the passing loop station

1 of either passenger or goods train, to pass a “special” train. This could be a break down train, milk train, or some other form, but should be consistent of the type of traffic that COULD POSSIBLY have been seen on a typical branch line. This “special” would only be run very occasionally. |